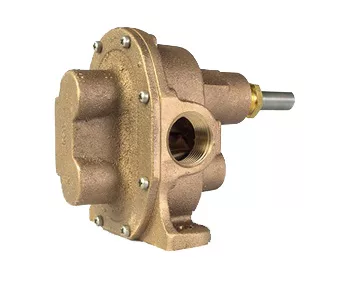

Bronze Rotary Gear standard pump housings and helical gears are made of top quality bronze. Shafts are stainless steel. Pumps are available with bronze bearings and grease fittings or with carbon bearings which require no lubrication. Dynamic seal arrangements include packing, lip, or mechanical seals for a variety of application requirements. Static cover o-ring seals eliminate gasket problems

- Bronze Corrosion Resistant Castings

- Special Cast Bronze Gears

- Stainless Steel Shafts & Fasteners

- Heavy Duty Carbon Bearings (Self Lubricating)

- Positive Displacement Flow

Bronze Rotary Gear pumps are of the external gear positive displacement type, displacing a finite volume of fluid with each shaft revolution. As such, capacity varies in direct proportion to pump speed. They are suited to handle clear lubricating and non-lubricating fluids, with PH ranging from 4 to 11, and temperatures to 400F. These pumps handle viscous fluids to 100,000 cps (462000 SSU) at reduced shaft speeds, with flow rates to 175 GPM (662 LPM), differential pressures to 150 psig (10.3 BAR), and suction lift capability to 20 feet (6.1 meters) for new pumps.

Bronze Gear Pump – N4000

Pump housings and gears are made of top quality bronze, shafts are 303 stainless steel. Bearings are made of high performance carbon-graphite material selected for wear resistance and long service life. Gear pumps are positive displacement pumps. Each shaft revolution displaces a definite amount of liquid relatively unaffected by the backpressure in the discharge line. Shaft speed and flow are directly proportional.

Features

- Bronze Corrosion Resistant Castings

- Special Cast Bronze Helical Gears For Quiet Operation

- Stainless Steel Shafts & Fasteners

- Synthetic Braided Compression Packing (with Polytetrafluoroethylene (PTFE) dispersion) is Standard

- Optional Lip Seals Are Available

- Positive Displacement Flow

- Bronze Bearing Surfaces With Grease Fittings

Performance

- Max Flow: 10.56 GPM – 40 LPM

- Max Pressure: 150 PSI – 10 BAR

DRIVE

Either direct drive with flexible coupling or pulley drive can be used. Make sure both flexible coupling halves are properly aligned. When using a pulley, do not over tighten the belt. Also, to absorb belt side thrust at higher pressures and larger size pumps, an external ball bearing support is recommended – consult factory.

LIQUIDS & TEMPERATURES

Service life will be increased substantially if the liquid pumped is clean and has some degree of lubricity. These positive displacement pumps have tight tolerances. Fine abrasives like sand, silt, or powders in suspension will accelerate pump wear and reduce throughput. Liquids compatible with bronze and stainless steel can be pumped providing proper seal has been specified (see chemical compatibility or check factory). No carbon bearings used. When possible, flush the pump after each usage. Temperature extremes are detrimental to service life and should be avoided. Basic metals of construction allow a temperature range of -40°F to 400°F. Some lip seal elastomers have a limit of 212°F. (see engineering data or check factory). Allowing a liquid to freeze in the pump can cause damage.

SUCTION LIFT

Close tolerances and the positive pumping action make the rotary gear pump capable of lifting water on the suction side as high as 20 feet. Though gear pumps are self priming, a foot valve is recommended. If possible, wet the gears with liquid to be pumped for the first dry start. Liquid retained in the system and gear chambers serves to “wet” the pump on subsequent starts.

*For pressures over 100 psi, the above selections are suitable for pumping fluids with lubricity (e.q. oils, polymers). Service life will decrease for fluids without lubricity (e.q. water, solvents).

EXPLODED VIEW & PARTS LIST

The pump by-pass is not intended to be a metering or flow control device. Its main purpose is to function as a pressure relief when the desired set point is exceeded, overheating can occur within 5 -10 minutes if the discharge line is completely shut off for extended periods. Reversing rotation reverses the “IN” and “OUT” ports and the location of the by-pass ports have to be reversed. The by-pass valve is factory set at 50 p.s.i. To increase the set point, turn the bypass valve adjusting screw in a clockwise direction.

Bronze Gear Pump – N7000

Pump housings and gears are made of top quality bronze, shafts are 303 stainless steel. Bearings are made of high performance carbon-graphite material selected for wear resistance and long service life. Gear pumps are positive displacement pumps. Each shaft revolution displaces a definite amount of liquid relatively unaffected by the backpressure in the discharge line. Shaft speed and flow are directly proportional.

Features

- Bronze Corrosion Resistant Castings

- Special Cast Bronze Gears

- Stainless Steel Shafts & Fasteners

- Formed Ring Seal Packing (Lip & Mechanical Seals on Special Order)

- Heavy Duty Carbon Bearings (Self Lubricating)

- Positive Displacement Flow

Performance

- Max Flow: 19.85 GPM – 75.14 LPM

- Max Pressure: 150 PSI – 10 BAR

DRIVE

DRIVE Either direct drive with flexible coupling or pulley drive can be used. Make sure both flexible coupling halves are properly aligned. When using a pulley, do not over tighten the belt. Also, to absorb belt side thrust at higher pressures and larger size pumps, an external ball bearing support is recommended – consult factory.

LIQUIDS & TEMPERATURES

Service life will be increased substantially if the liquid pumped is clean and has some degree of lubricity. These positive displacement pumps have tight tolerances. Fine abrasives like sand, silt, or powders in suspension will accelerate pump wear and reduce throughput. Liquids compatible with bronze and stainless steel can be pumped providing proper seal has been specified (see chemical compatibility or check factory). When possible, flush the pump after each usage. Temperature extremes are detrimental to service life and should be avoided. Basic metals of construction allow a temperature range of -40°F to 400°F. Some lip and mechanical seal elastomers have a limit of 212°F. (see engineering data or check factory). Allowing a liquid to freeze in the pump can cause damage.

*For pressures over 100 psi, the above selections are suitable for pumping fluids with lubricity (e.q. oils, polymers). Service life will decrease for fluids without lubricity (e.q. water, solvents).

SUCTION LIFT

Close tolerances and the positive pumping action make the rotary gear pump capable of lifting water on the suction side as high as 20 feet. Though gear pumps are self priming, a foot valve is recommended. If possible, wet the gears with liquid to be pumped for the first dry start. Liquid retained in the system and gear chambers serves to “wet” the pump on subsequent starts.

EXPLODED VIEW & PARTS LIST

The pump by-pass is not intended to be a metering or flow control device. Its main purpose is to function as a pressure relief when the desired set point is exceeded, overheating can occur within 5 -10 minutes if the discharge line is completely shut off for extended periods. Reversing rotation reverses the “IN” and “OUT” ports and the location of the by-pass ports have to be reversed. The by-pass valve is factory set at 50 p.s.i. To increase the set point, turn the bypass valve adjusting screw in a clockwise direction.

Bronze Gear Pump – N9000

Pump housings and gears are made of top quality bronze, shafts are 303 stainless steel. Bearings are made of high performance carbon-graphite material selected for wear resistance and long service life. Gear pumps are positive displacement pumps. Each shaft revolution displaces a definite amount of liquid relatively unaffected by the backpressure in the discharge line. Shaft speed and flow are directly proportional.

The pump by-pass is not intended to be a metering or flow control device. Its main purpose is to function as a pressure relief when the desired set point is exceeded, overheating can occur within 5 -10 minutes if the discharge line is completely shut off for extended periods. Reversing rotation reverses the “IN” and “OUT” ports and the location of the by-pass ports have to be reversed. The by-pass valve is factory set at 50 p.s.i. To increase the set point, turn the bypass valve adjusting screw in a clockwise direction.

Features

- Bronze Corrosion Resistant Castings

- Special Cast Bronze Gears

- Stainless Steel Shafts & Fasteners

- Formed Ring Seal Packing (Lip & Mechanical Seals on Special Order)

- Heavy Duty Carbon Bearings (Self Lubricating)

- Positive Displacement Flow

Performance

- Max Flow: 23.33 GPM – 88.31 LPM

- Max Pressure: 150 PSI – 10 BAR

DRIVE

Either direct drive with flexible coupling or pulley drive can be used. Make sure both flexible coupling halves are properly aligned. When using a pulley, do not over tighten the belt. Also, to absorb belt side thrust at higher pressures and larger size pumps, an external ball bearing support is recommended – consult factory.

LIQUIDS & TEMPERATURES

Service life will be increased substantially if the liquid pumped is clean and has some degree of lubricity. These positive displacement pumps have tight tolerances. Fine abrasives like sand, silt, or powders in suspension will accelerate pump wear and reduce throughput. Liquids compatible with bronze and stainless steel can be pumped providing proper seal has been specified (see chemical compatibility or check factory). When possible, flush the pump after each usage. Temperature extremes are detrimental to service life and should be avoided. Basic metals of construction allow a temperature range of -40°F to 400°F. Some lip and mechanical seal elastomers have a limit of 212°F. (see engineering data or check factory). Allowing a liquid to freeze in the pump can cause damage.

SUCTION LIFT

Close tolerances and the positive pumping action make the rotary gear pump capable of lifting water on the suction side as high as 20 feet. Though gear pumps are self priming, a foot valve is recommended. If possible, wet the gears with liquid to be pumped for the first dry start. Liquid retained in the system and gear chambers serves to “wet” the pump on subsequent starts.

*For pressures over 100 psi, the above selections are suitable for pumping fluids with lubricity (e.q. oils, polymers). Service life will decrease for fluids without lubricity (e.q. water, solvents).

Bronze Gear Pump – N994

Pump housings and gears are made of top quality bronze, shafts are stainless steel 303. Bearings are made of high performance carbon-graphite material selected for wear resistance and long service life. Gear pumps are positive displacement pumps. Each shaft revolution displaces a definite amount of liquid relatively unaffected by the back pressure in the discharge line. Shaft speed and flow are directly proportional.

Features

- Bronze Construction with Stainless Steel Shafts

- Helical gears for quiet operation

- Easy Field Assembly to Motors

- Self-Lubricating Carbon Bearings

- O-ring seal for maximum leak protection

- For clutch driven version, see N994-38

- Lip or Mechanical Seal

- For Danfoss hydrolic motor driven pump units

Performance

- Max Flow: 10.6 GPM – 40 LPM

- Max Pressure: 150 PSI – 10 BAR

- Max Pressure: 300 PSI – 20 BAR (N994 High Pressure Model)

DRIVE

Close coupled pumps are mounted directly to the electric motor by means of a suitable adapter bracket. The pump drive shaft is connected to the motor shaft by a flexible coupling.

LIQUIDS & TEMPERATURES

These pumps are suitable for all liquids that are compatible with bronze. Most common liquids are water, oil, and mild chemicals in the pH-range of 4 to 11. Viscous liquids require reduced shaft speeds of 1150 RPM or lower. Consult factory. Liquids containing solids, abrasives, powders or paint pigments are definitely not recommended for gear pumps. If abrasives are unavoidable, use a very low shaft speed. See price book for the recommended liquid temperature range of lip and mechanical seals. Freezing of water-filled pumps can cause damage and must be avoided. Oils at low temperatures are very viscous requiring a lower speed or extra power.

SUCTION LIFT

As a general rule, the suction lift should be kept at an absolute minimum by placing the pump as close to the liquid source as possible. A gear pump in new condition can lift 20 feet of water in the suction line. A foot valve (preferably with built-in strainer) is recommended at the beginning of the suction line. For a first start-up, the pump should be primed to avoid dry running. Minimum size of the suction pipe is the size of the pump inlet port. For longer suction lines (over 3 feet), or for viscous liquids, the pipe size should be at least one size or two sizes larger than the pump inlet port.

ROTATION AND RELIEF VALVE

The relief valve is not intended to be a metering or flow control device. Its main purpose is to function as a discharge pressure relief when the spring tension is exceeded by the discharge pressure. Overheating can occur within 5-10 minutes if the discharge line is completely shut off for extended periods. Unless otherwise specified, the pump motor unit is supplied by the factory for shaft rotation clockwise from shaft end. Reversing the motor rotation will reverse the “in” and “out” ports and also requires changing the relief valve location. The relief valve is always on the discharge side in this pump series. The factory pressure setting is 50 PSIG. To increase pressure, turn the relief valve adjusting screw in a clockwise direction. To reverse single phase motors, find instructions on the inside of the junction box cover or on the name plate of the motor. Three phase motors are not wired for any particular rotation. They can be reversed by interchanging any two (2) wires of the three (3) wire leads.

Bronze Gear Pump – N970

Pump housings and gears are made of top quality bronze, shafts are 303 stainless steel. Bearings are made of high performance carbon-graphite material selected for wear resistance and long service life. Gear pumps are positive displacement pumps. Each shaft revolution displaces a definite amount of liquid relatively unaffected by the back pressure in the discharge line. Shaft speed and flow are directly proportional.

Features

- Bronze Construction with Stainless Steel Shafts

- Helical gears for quiet operation

- Easy Field Assembly to Motors

- Self-Lubricating Carbon Bearings

- O-ring seal for maximum leak protection

- For clutch driven version, see N970-38

Performance

- Max Flow: 19.5 GPM – 73.82 LPM

- Max Pressure: 150 PSI – 10 BAR

DRIVE

Close-coupled pumps are mounted directly to the electric motor by means of a suitable adapter bracket. The pump drive shaft is connected to the motor shaft by a flexible coupling.

LIQUIDS & TEMPERATURES

These pumps are suitable for all liquids that are compatible with bronze. Most common liquids are water, oil, and mild chemicals in the pH-range of 4 to 11. Viscous liquids require reduced shaft speeds of 1150 RPM or lower. Consult factory. Liquids containing solids, abrasives, powders or paint pigments are definitely not recommended for gear pumps. If abrasives are unavoidable, use a very low shaft speed. The recommended liquid temperature range is 32°F to 140°F for longest pump life. If more extreme temperature conditions exist, our factory should be consulted. Freezing of water-filled pumps can cause damage and must be avoided. Oils at low temperatures are very viscous requiring a lower speed or extra power.

SUCTION LIFT

As a general rule, the suction lift should be kept at an absolute minimum by placing the pump as close to the liquid source as possible. A gear pump in new condition can lift 20 feet of water in the suction line. A foot valve (preferably with built-in strainer) is recommended at the beginning of the suction line. For a first start-up, the pump should be primed to avoid dry running. Minimum size of the suction pipe is the size of the pump inlet port. For longer suction lines (over 3 feet), or for viscous liquids, the pipe size should be at least one size or two sizes larger than the pump inlet port.

ROTATION AND RELIEF VALVE

The relief valve is not intended to be a metering or flow control device. Its main purpose is to function as a discharge pressure relief when spring tension is exceeded by the discharge pressure. Overheating can occur within 5-10 minutes if the discharge line is completely shut off for extended periods. Unless otherwise specified, the pump motor unit is supplied by the factory for shaft rotation clockwise from shaft end. Reversing the motor rotation will reverse the “in” and “out” ports and also requires changing the relief valve location. The relief valve is always on the discharge side in this pump series. The factory pressure setting is 50 PSIG. To increase pressure, turn the relief valve adjusting screw in a clockwise direction. To reverse single phase motors, find instructions on the inside of the junction box cover or on the nameplate of the motor. Three phase motors are not wired for any particular rotation. They can be reversed by interchanging any two (2) wires of the three (3) wire leads.

*For pressures over 100 psi, the above selections are suitable for pumping fluids with lubricity (e.q. oils, polymers). Service life will decrease for fluids without lubricity (e.q. water, solvents).

Bronze Gear Pump – N990

Pump housings and gears are made of top quality bronze, shafts are 303 stainless steel. Bearings are made of high performance carbon-graphite material selected for wear resistance and long service life. Gear pumps are positive displacement pumps. Each shaft revolution displaces a definite amount of liquid relatively unaffected by the backpressure in the discharge line. Shaft speed and flow are directly proportional.

Features

- Bronze Construction with Stainless Steel Shafts

- Helical Gears For Quiet Operation

- Easy Field Assembly to Motors

- Self-Lubricating Carbon Bearings

- O-Ring Seal For Max. Leak Protection

- For Clutch Version See N990-38

- For Air Motor Driven Version, See N990S15H-T34

Performance

- Max Flow: 23.0 GPM – 87.06 LPM

- Max Pressure: 150 PSI – 10 BAR

DRIVE

Close-coupled pumps are mounted directly to the electric motor by means of a suitable adapter bracket. The pump drive shaft is connected to the motor shaft by a flexible coupling.

LIQUIDS & TEMPERATURES

These pumps are suitable for all liquids that are compatible with bronze. Most common liquids are water, oil, and mild chemicals in the pH-range of 4 to 11. Viscous liquids require reduced shaft speeds of 1150 RPM or lower. Consult factory. Liquids containing solids, abrasives, powders or paint pigments are definitely not recommended for gear pumps. If abrasives are unavoidable, use a very low shaft speed. The recommended liquid temperature range is 32°F to 140°F for longest pump life. If more extreme temperature conditions exist, our factory should be consulted. Freezing of water-filled pumps can cause damage and must be avoided. Oils at low temperatures are very viscous requiring a lower speed or extra power.

SUCTION LIFT

As a general rule, the suction lift should be kept at an absolute minimum by placing the pump as close to the liquid source as possible. A gear pump in new condition can lift 20 feet of water in the suction line. A foot valve (preferably with built-in strainer) is recommended at the beginning of the suction line. For a first start-up, the pump should be primed to avoid dry running. Minimum size of the suction pipe is the size of the pump inlet port. For longer suction lines (over 3 feet), or for viscous liquids, the pipe size should be at least one size or two sizes larger than the pump inlet port.

ROTATION AND RELIEF VALVE

The relief valve is not intended to be a metering or flow control device. Its main purpose is to function as a discharge pressure relief when the spring tension is exceeded by the discharge pressure. Overheating can occur within 5-10 minutes if the discharge line is completely shut off for extended periods. Unless otherwise specified, the pump motor unit is supplied by the factory for shaft rotation clockwise from shaft end. Reversing the motor rotation will reverse the “in” and “out” ports and also requires changing the relief valve location. The relief valve is always on the discharge side in this pump series. The factory pressure setting is 50 PSIG. To increase pressure, turn the relief valve adjusting screw in a clockwise direction. To reverse single phase motors, find instructions on the inside of the junction box cover or on the nameplate of the motor. Three phase motors are not wired for any particular rotation. They can be reversed by interchanging any two (2) wires of the three (3) wire leads.

*For pressures over 100 psi, the above selections are suitable for pumping fluids with lubricity (e.q. oils, polymers). Service life will decrease for fluids without lubricity (e.q. water, solvents).