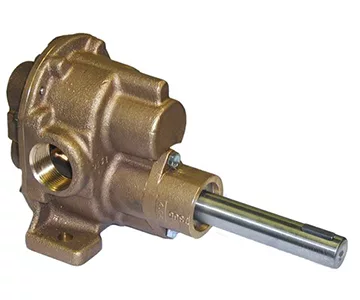

Bronze Gear Pump – N11500

Pump housings and gears are made of top quality bronze, shafts are 303 stainless steel. Bearings are made of high performance carbon-graphite material selected for wear resistance and long service life. Gear pumps are positive displacement pumps. Each shaft revolution displaces a definite amount of liquid relatively unaffected by the backpressure in the discharge line. Shaft speed and flow are directly proportional.

Features

- Bronze Corrosion Resistant Castings

- Stainless Steel Shafts & Fasteners

- Self-Lubricating Carbon Bearings

- Acrylic Graphite Packing or Fluoroelastomer (S10) – Polytetrafluoroethylene (PTFE) (S11) Lip

- For Mechanical Seals, see Models N11HDM

- For Heavy Pulley loads, see Model N11HDP

Performance

- Max Flow: 61 GPM – 230.91 LPM

- Max Pressure: 150 PSI – 10.35 BAR

DRIVE

Either direct drive with flexible coupling or pulley drive can be used. For pulley driven pumps, a pillow block bearing must be used at the drive shaft end to absorb the belt forces. The drive shaft is sufficiently long enough to accommodate a pillow block in addition to the pulley. Correct alignment is absolutely essential for satisfactory pump life. Recheck alignment after the piping has been connected to the pump.

LIQUIDS & TEMPERATURES

Service life will be increased substantially if the liquid pumped is clean and has a lubricity value. These pumps have extremely close tolerances. Fine abrasives like sand, silt, or powders in suspension will destroy pumping ability. Liquids compatible with bronze, stainless steel and the acrylic graphite packing can be pumped. Solvent resistant packings and Polytetrafluoroethylene (PTFE) packings are also available. See a chemical compatibility table or check factory. When possible, flush the pump with water after using. Temperature extremes are detrimental to service life and should be avoided. Basic metals of construction allow temperature range of -400°F to 4000°F. The acrylic graphite packing is rated to 5000°F. Freezing liquid in the pump can deform or damage the pump.

Viscous liquids such as molasses or oils require a lower pumping speed, in extreme cases as low as 200 R.P.M. Consult factory for recommended speeds and increased horsepower requirements. Large suction lines are required to prevent cavitation, which can cause pump destruction. Liquids with specific gravities heavier than water such as dry cleaning fluids require an increase in motor horsepower directly proportional to the increase in specific gravity over water.

SUCTION LIFT

A rotary gear pump is capable of lifting water on the suction side as high as 20 feet. Though gear pumps are self-priming, a foot valve is recommended. For pumping water directly from streams or ponds, a wire mesh strainer must be used at the beginning of the suction line to prevent stones from entering the pump. Strainer and foot valve are commercially available as combination units.