Saltwater Reverse Osmosis (SWRO) Process

Saltwater reverse osmosis (SWRO) is a process that uses a semi-permeable membrane to remove salts and other impurities from seawater, producing fresh water. The process typically involves the following steps:

- Pre-treatment: Seawater is first pre-treated to remove large particles, debris, and other impurities that could clog or damage the membrane. This is done by passing the water through a series of filters, such as sand filters, multimedia filters, and cartridge filters.

- High-pressure pumping: The pre-treated seawater is then pumped at high pressure (typically between 800 and 1,200 psi) into the SWRO system. The pressure is necessary to overcome the osmotic pressure of seawater and force the water through the semi-permeable membrane.

- Membrane filtration: The SWRO system contains one or more semi-permeable membranes, which are typically made of thin film composite (TFC) or cellulose acetate (CA). The membranes have tiny pores that allow water molecules to pass through while blocking salt ions and other impurities.

- Fresh water recovery: The purified water that passes through the membrane is collected and stored in a clean water tank. Depending on the system design, the water may be further treated with post-treatment processes, such as carbon filtration, disinfection, and pH adjustment, before it is ready for use.

- Concentrate disposal: The seawater that does not pass through the membrane, along with the impurities that were blocked by the membrane, is called the concentrate or brine. This concentrate is discharged back into the ocean or other disposal methods.

SWRO is an energy-intensive process, as the high pressure required for membrane filtration requires significant energy input. However, the process is highly effective at producing high-quality fresh water from seawater. Thus, this is a popular method for meeting water demand in coastal regions and other areas where fresh water is scarce.

Reverse Osmosis with Cat Pumps

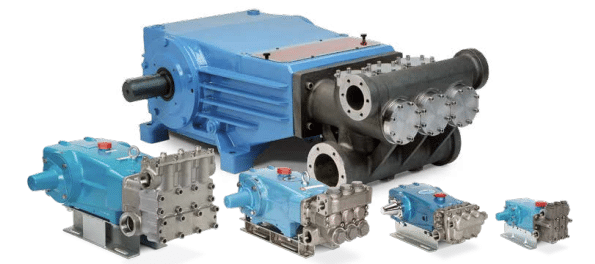

Overseas Motors is proud to be a partner in this process, with us supplying Cat Pumps high pressure pumps to various industries

Cat Pumps has earned the reputation as the industry leader for high-pressure pumps due to long product life and dependable performance. Cat Pumps produces the highest-quality, longest lasting products by maintaining a rigorous zero defect quality assurance program to guarantee consistently high quality products.

References

Salt Water Reverse Osmosis

- Resorts

- Off-shore Platforms

- Military

Environmental Applications

- Industrial Waste Water Treatment

- Leachate Treatment

- Municipalities Produced Water Treatment

Special features:

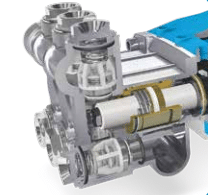

Cat Pumps designs and builds products to the highest quality levels. Hence, every design detail is optimized for product life and performance. Some features include :

- Specially formulated seals and high density, polished ceramic plungers. These typify the attention to design detail that results in thousands of hours of trouble-free service

- Stainless steel valves, seats and springs provide corrosion resistance, positive seating and long life

- Wet seal design increases service life by allowing pumped fluids to cool and lubricate the elastomers on both sides

Product Specification Range

A wide range of pump options are available, including a variety of products that meet industry certifications and directives:

- Flow: 0.13 to 240 gpm (0.49 to 908 lpm)

- Manifold Materials: Nickel Aluminium Bronze, 304 and 316 Stainless Steel, Duplex Stainless Steel. Other materials available on request

- Sealing Material: NBR, FPM, EPDM, PTFE, silicone-free and other materials available upon request

- Drives: Electric, Engine, Hydraulic, Pneumatic

Contact us now or learn more about our Cat Pumps Range Reverse Osmosis Range here.