There are many reasons why you have chosen to choose an AODD pump to pump your fluid and some may or may not include the following:

- You are operating in a hazardous area where electrical supply is not suitable.

- You like simple installation and operation.

- You can’t afford downtime and require the AODD pump to always stay primed.

- You are handling viscous liquids.

- You are handling abrasive materials.

- You are handing abrasive, corrosive or shear sensitive liquids.

How an AODD Pump works:

An AODD pump utilizes dual flexible diaphragms mounted to a shared shaft which moves back and forth repeatedly in strokes to pump fluids into and out of the pump’s fluid chamber. This movement creates a vacuum, which intakes fluid through an inlet port.

Key Factors to consider

What are you pumping?

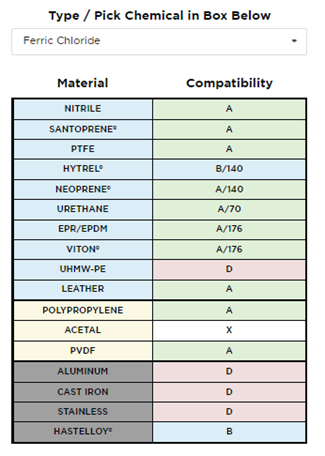

The Chemical Compatibility of the pump materials with the liquid that is being pumped sounds overly technical and not all of us are chemical engineers. Thankfully, our manufacturer, ARO, has published a very helpful Chemical Compatibility guide accessible here.

This should be balanced with the cost of the pump construction materials.

Take the above compatibility of Ferric Chloride as an example. There are many materials are compatible with the fluid, however, the most cost-efficient solution would be to use Santoprene and Polypropylene in your diaphragm pump.

Pumping Temperature:

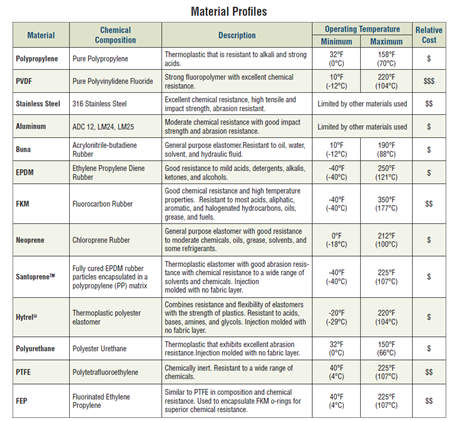

It is important to be aware of the temperature of the fluid being pumped for the selection of the material of the pump casing, seals, and diaphragms. As seen from the above material profiles, some materials have limited operating temperature bands that they can be most efficient in.

For temperature, there are 3 considerations:

1. Temperature limit of the manifolds (found in the operating manual)

2. Temperature limit of the elastomers (found in the material profiles above)

3. Temperature limit of chemicals with materials[1] (refer to chemical chart above)

For example, with Ferric Chloride, it is only compatible with EPR/EPDM up to 176 °F (27 °C).

[1] Maximum temperature is based on mechanical stress only. Certain chemicals may significantly reduce maximum safe operating temperature

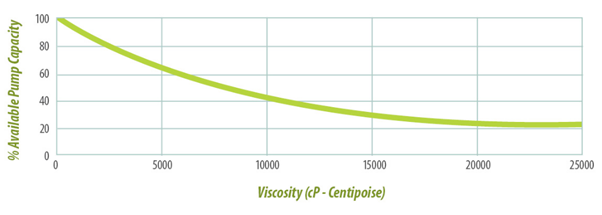

Viscosity of your fluid:

The efficiency of your fluid flow is also affected by the viscosity of the fluids pumped. Viscous liquids affect the flow of the fluid and your operating performance will be compromised. Our Manufacturer Finish-Thompson, has produced a useful guide on viscosity for us.

Our team would be happy to advise on the operating capabilities and your specific needs.

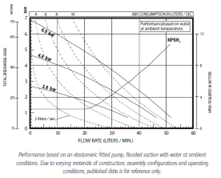

Required Pump Performance:

Flow

How much liquid do you need and how fast must you fill up your drum? If you are operating a factory where your fluid needs to be pumped into a 200 litre drum within minutes, you would need to size up your pump to meet your needs.

Discharge Head

What is the distance you need to deliver your fluids over? The distance from the highest vertical fluid point above or below the pump is your estimated requirement. For example, if a pump has to draw from a sump and the worst-case depth of the fluid level below the pump is 5 meters, then your operation will minimally require a 5m head as your operating pressure. Do make sure to account for friction head, which is the resistance of the fluid when driven by the pump through the pipe system.

Volume of air required

How much volume of air (L/s / Scfm) and the air pressure (Psi / Bar) that the pump requires at various operating levels also determines how much as well as how far the material can be supplied at various operating levels of the pump.

Still have any queries? Contact us now.

Disclaimer:

Please note that the views and opinions expressed on this article are for informational purposes only and solely belong to Overseas Motors (Pte) Ltd (the “Company”). The opinions may not reflect or represent the views of the third parties (manufacturers, suppliers, or experts) mentioned in the article. Any views and opinions are not intended to malign or misrepresent any individuals, companies, or other parties.

The Company makes no representations as to the accuracy or completeness of any information on this article or found by following any link on this site. The Company has made all attempts to ensure the information on this article is complete and accurate, however, this information may contain any number of errors or inaccuracies. We shall assume no responsibility for such errors or omissions and reserve the right to make amendments to any of the information stated in this article. We shall not be liable for any losses, injuries or damages that arise from the display of the article and the information contained therein.