How does the filter press process work?

The filter press process works by using pressure to force the liquid through a series of filter plates, which are typically made of polypropylene or stainless steel.

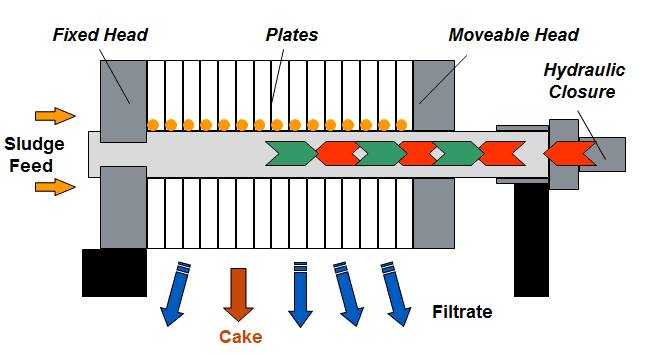

The filter press consists of a series of filter plates that are stacked together and held in place by a frame. The filter plates have a recessed chamber in which the filter media, such as filter cloth or paper, is placed. The liquid to be filtered is pumped into the filter press and is distributed evenly across the filter plates.

As the liquid is forced through the filter media, the solid particles are captured and retained on the surface of the filter media. The filtered liquid, also known as filtrate, is collected in a chamber or manifold located at the bottom of the filter press.

Batch Process

The filter press operates in a batch process, each filter cycle is called a “press cycle.” During a press cycle, the filter press is filled with the liquid to be filtered, and the filter plates are pressed together to apply pressure. The press cycle continues until the filter cakes build up on the filter plates and the filtrate becomes clear.

After the press cycle, the filter cakes are removed from the filter plates, and the filter plates are cleaned and prepared for the next press cycle. The filter cakes can be disposed of or further processed for the recovery of solids.

Filter press are widely used in the treatment of industrial and municipal wastewater, particularly in applications where large volumes of sludge are produced. They are also used in other industries such as food and beverage, mining, and chemical processing. With their high efficiency and cost-effectiveness, filter presses have become a popular choice for wastewater treatment in a variety of applications.

Sandpiper for filter press applications

Our full range of mobile pump solutions for water and wastewater applications are built for tough jobs. When you need a reliable, cost effective pump for handling and transferring fluids with high solids content, you can count on Sandpiper.

Because waste water can be highly abrasive and chemically aggressive, Sandpiper diaphragm water pumps are designed to outperform the competition. They provide a more robust seal than electric pumps, which rely on mechanical seals that can leak and cause hazards.