Throughout our many years of experience, we have noticed that manufacturers tend to err on the side of caution and recommend more stringent maintenance routines. As pump downtime in many companies could result in huge operating expenses, an IOT solution is one that can improve operational efficiency.

Can’t see the benefits? Check out our sample value proposition based on rough estimates below.

| Item | Notes | Estimated Savings / Year |

| Seal Change* | 3000 hours (18 months) instead of 1500 hours (6 months) 1 x Seal Kit = US$ 921.00 ~ S$ 1293.54 | S$ 1,293.54 |

| Valve Change* | 6000 hours (24 Months) instead of 3000 hours (12 Months) 2 x Valve Kit = US$1495.00 x 2 = US$ 2,990 ~ S$ 4199.44 | S$ 4,199.44 |

| Time savings | 25% estimated increase in operational efficiency Improvement in Maintenance Schedule through Predictive Maintenance Reduced need for onsite inspection work | – |

| Potential Energy Savings | 15% estimated savings | – |

| Reduction in Downtime | 3 – 4 Working Days / year | – |

| Total: | S$ 5,492.98 |

Our offerings:

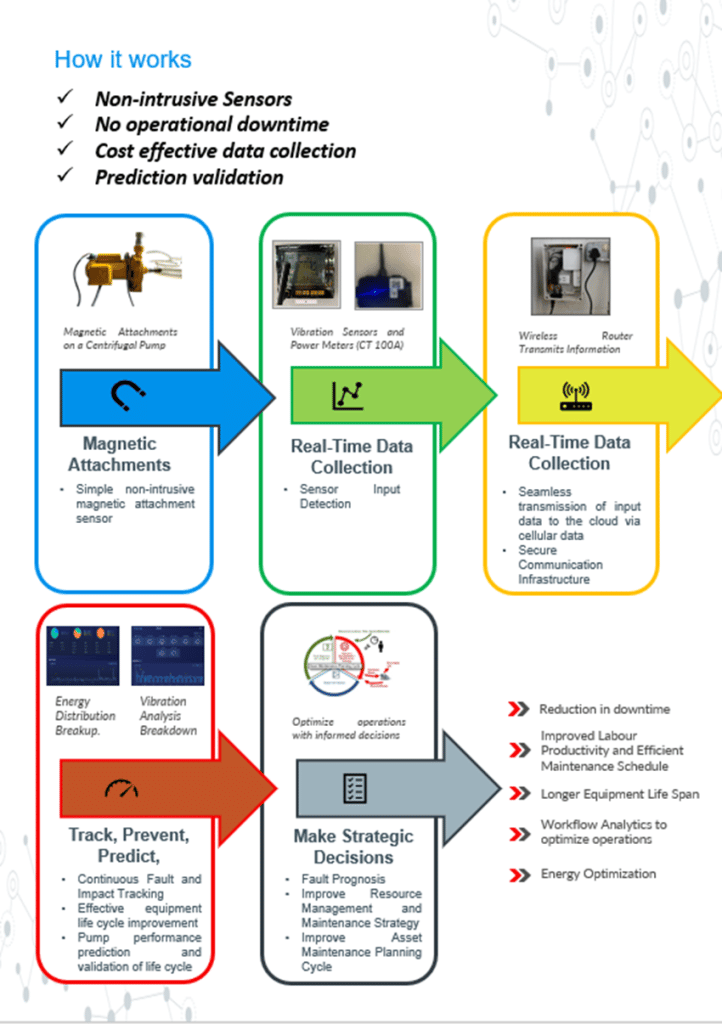

As a high-quality pump supplier, Overseas Motors intend to perform different levels of maintenance for our clients. We provide preventive and predictive maintenance for our clients as a premium added value service and for our clients to have close monitoring of their pump systems, developing a “smart pump” concept.

There are three main ways we can assist your company to monitor your pump:

Vibration Analysis: Vibration monitoring is an effective way to detect and prevent premature and even catastrophic equipment failure. In addition to bearing wear, vibration often indicates faults such as imbalance, misalignment and looseness.

Temperature Analysis: Analyzing sudden increases in temperature can help to prevent other parts of the pump from being damaged. Overheating arises from bearing wear, misalignments and imbalances.

Energy Distribution Breakup: Sudden increases in energy consumption could indicate improper installation, equipment wear and tear or deposits accumulating in the piping. IOT solutions also result in high energy savings and reduce energy consumption.

We provide:

-

- Preventive Maintenance

- Preventive Maintenance

-

- Regular reporting on pump health

- Regular reporting on pump health

-

- Real-time updates on any emerging faults

- Real-time updates on any emerging faults

-

- Data collection and Storage

- Data collection and Storage

Contact us now for a confidential discussion if:

-

- Operations are time sensitive and critical.

-

- There is manual data collection and logging.

-

- Maintenance is time-consuming and costly.

-

- Energy consumption is high.