Blue-White® Peristaltic Metering Pumps

Blue-White’s FLEXFLO® Peristaltic Metering Pumps (Peristaltic Dosing Pumps) deliver precision fluid metering and accurate dispensing with a wide range of control capabilities. Peristaltic pumps have a gentle, nearly pulsation-free pumping action that makes them ideal for difficult-to-pump fluids such as gaseous chemicals, shear-sensitive fluids, viscous slurries and solids, and fluids with low moisture levels.

How Do Peristaltic Pumps Work?

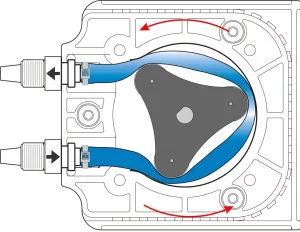

Peristaltic pumps (hose or tube pumps) are a type of positive displacement pump that work using progressive squeezing action. Fluid is pumped through flexible tubing in a peristaltic motion. As the pump’s rotor turns, the roller assembly rollers squeeze the tubing to force the fluid through the discharge line.

When the squeeze pressure is released, the tube rebounds to its original state, creating a vacuum and drawing fluid into the suction side of the pump. The combination of suction and discharge principles produces a powerful yet gentle pumping action.

Advantages of a Peristaltic Metering Pump

Won’t vapor lock or lose prime

Eliminate downtime and disruption in your process

No check-valves to clean and replace

Less maintenance and lower cost-of-ownership

30ft (9.1m) of suction lift

Reduce downtime with powerful suction lift capabilities

Gentle low-shear pumping action

Ideal for a low-shear sensitive product including flocculants

Applications

- Wastewater Treatment

- Potable Water Treatment

- Food and beverage

- Pulp and Paper

- Cooling Tower Water Treatment

- Metal Finishing

- Plastics Production

- General Chemical Metering

Peristaltic Pumps FAQ

A peristaltic pump is a type of positive displacement pump that works by squeezing a flexible tube or hose to create a flow of fluid. The pump consists of a rotating rotor with a number of rollers that compress the tube, creating a series of cavities or “pockets” that move fluid through the pump in a controlled manner. As the rotor turns, the rollers squeeze the tube, forcing fluid to move through the pump.

Peristaltic metering pumps excel at pumping dirty fluids that contain particulate matter into lower-pressure systems because they have no check valves to clog. The gentle forces created during the peristaltic pumping action will not damage delicate fluids within the tube. Peristaltic pumps are also ideal for pumping gaseous chemicals such as sodium hypochlorite because they can pass slugs of gas safely, eliminating the chance of vapor lock. In addition, the interior tubing and the fittings are the only part of the pump to come into contact with the fluid, so they’re an excellent option for pumping flavorings, scents, colorings, additives, vitamins, minerals in food and beverage applications. Blue-White’s tubes comply with FDA21 CFR, 117.2600 criteria for food processing.

Peristaltic pumps do not require foot or back pressure valves to function properly. They are capable of suctioning dry products and do not need to be primed to operate, eliminating the need for a foot valve. Neither do they require back pressure valves, as they can meter fluids at different pressures without the flow rate being affected. In addition, back pressure valves can shorten the tube life of a peristaltic pump by adding unnecessary back pressure.

The accuracy of the FLEXFLO peristaltic pumps is +/-5% full scale accuracy. If the pump is calibrated it becomes +/- 2%. These accuracy claims are only for water at 72⁰F with a 5-foot suction lift at atmospheric conditions of sea level.

Peristaltic pumps have powerful suction capabilities, with a suction lift capability of 30’ or 9.1m. They can also run dry without causing damage to the pump. (diaphragm pumps on the other hand need to be primed to function properly, adding down time to the process)