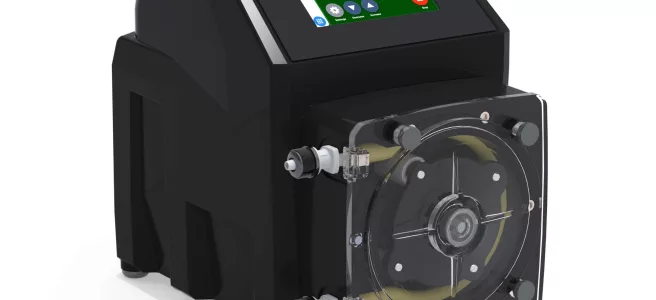

FLEXFLO® Peristaltic Metering Pump

Experience next-level chemical metering with the FLEXFLO® M3 Peristaltic Metering Pump. The M3 combines accurate metering at discharge pressures up to 125 PSI, intuitive icon-based touch screen controls, and IP rated M12 connection ports that protect against moisture, dust, vibration, and any temperature change.

M3 remote control signal options include Pulse, 4-20mA, Modbus TCP, EtherNet IP, and PROFIBUS for enhanced supervision and automation for critical metering and transfer applications.

Technical Overview:

| GPH | .0002 – 33.3 | Enclosure Rating | NEMA 4X (IP66) |

| LPH | .0007 – 126 | Standards | cETLus, CE, NSF61 |

| mL/min | .0117 – 2100 | Control Methods | Manual, Remote Analog/Digital, EtherNet/IP, Modbus TCP/IP, PROFIBUS |

| Pressure | 125 PSI (8.6 Bar) | Power Supply | 100 to 240VAC-50/60Hz |

Features

Benefits:

- Self-priming – even against maximum line pressure. By-pass valves are not required. Cannot vapor lock or lose prime. 30ft of suction lift. Gentle low shear pumping action.

- Tube Failure Detection (TFD) senses tube rupture by detecting chemical in the pump head. No false triggering – Patented

- Optional dual channel tube design for optimum performance and pressure capability

Communication and Interface:

- 5” touchscreen color LCD display

- User-friendly configurations

- Control Methods:

- Manual Control

- 4-20mA Input

- Remote Start/Stop

- Pulse Input

- Frequency Input

- EtherNet/IP

- Modbus TCP/IP

- PROFIBUS

- Alarm Outputs

- FVS

- Relay Ouput

Superior Design:

- 5 Year Warranty

- 10,000:1 turndown ratio

- NEMA 4X (IP66) wash-down, chemically resistant enclosure

- Heavy duty rotor means no flexing and increased accuracy with no metal springs or hinges to corrode.

Safety Features:

- Tube Failure Detection (TFD) senses tube rupture preventing hazardous chemical spills

- Security programmable 6-digit password to prevent tampering

Optional Components Available:

- Mounting Extended Brackets (72000-380) – 1 Pair, SS, 4 SS Screws

What’s Included:

- M3 Peristaltic Metering Pump

- Two tube assemblies

- Tube installation tool

- Mounting hardware kit

Specifications

| Maximum Working Pressure (excluding pump tubes) 125 psig (8.6 bar) NOTE: See individual pump tube assembly maximum pressure ratings. |

Maximum Fluid Temperature (excluding pump tubes) 185 °F (85 °C) NOTE: See individual pump tube assembly max. temperature ratings. |

Maximum Viscosity 12,000 Centipoise Maximum Suction Lift |

| Ambient Operating Temperature 14 °F to 115 °F (-10 °C to 46 °C) |

Ambient Storage Temperature -40 °F to 158 °F (-40 °C to 70 °C) |

Operating Voltage 115VAC/60Hz, 1ph (2.0 Amp Maximum) 230VAC/60Hz, 1ph (1.0 Amp Maximum) 220VAC/50Hz, 1ph (1.0 Amp Maximum) 240VAC/50Hz, 1ph (1.0 Amp Maximum) 230VAC/50Hz, 1ph (2.0 Amp Maximum) |

| Power Cord Options 115V60Hz = NEMA 5/15 (USA) 230V60Hz = NEMA 6/15 (USA) 220V50Hz = CEE 7/VII (EU) 240V50Hz = AS 3112 (Australia/New Zealand) 230V50Hz = BS 1363/A (UK) |

Motor Brushless DC, 1/4 hp |

Motor Speed Adjustment Range 10,000:1 (0.01% – 100% motor speed) Max RPM = 125 |

| Motor Speed Adjustment Resolution 0.1% increments > 1% motor speed and < 100% 0.01% increments < 1% motor speed |

Display 5” touchscreen color LCD, UV resistant. Display Languages |

|

| Maximum Overall Dimensions 8-1/4”W x 11-3/4”H x 13-1/4”D (20.9W x 29.8H x 34.5D cm) |

Product Weight 25.4lb. (11.5 Kg) |

Security Programmable 6-digit password |

| Approximate Shipping Weight 30 lb. (13.6 Kg) |

Enclosure NEMA 4X (IP66) wash-down, chemically resistant enclosure |

RoHS Compliant Yes |

| Standards cETLus, CE, NSF61 |